Failure to use the right safety glove is the second leading cause of workplace injuries.

So, it only makes sense that safety managers understand the different kinds of hand protection that is available. Were you aware that the average cost of a single hand injury can range between $22-30 thousand dollars? The cost may not just be the actual stitches, but it does include loss of production, clean up, medical costs and rehabilitation.

Do you have a few thousand dollars lying around to cover those costs?

- We have covered quite a bit of topics relating to personal protective equipment and the new ASTM standard F2992/F2992M-15, so check out our library of information in case you need more info!

Let’s focus on cut gloves and the Cut Risk Hazard Matrix (CRH). Once a safety manager decides that a cut resistant glove is the necessary PPE for the job, there are still more questions that need to be answered. Unfortunately, this is the point where most fall short.

Cut resistant gloves are not all created equal. They are designed specifically for certain applications and the risks associated with the job. Not choosing a safety glove based off of the level of protection it provides is like using a hammer to do the job of hacksaw. Come on, you know better than that!

First, let’s talk about hand trauma. What are the different types of trauma and how does it happen?

Incision: Typically due to coming in contact with a razor sharp edge and creates a smooth and neat wound

Laceration: Contact with jagged and rough edges usually leads to a laceration which leaves a torn open wound

Abrasion: This usually occurs when skin is scraped or rubbed by a flat and rough edge

Contusion: In this situation, skin is not penetrated, but the impact causes broken blood vessels

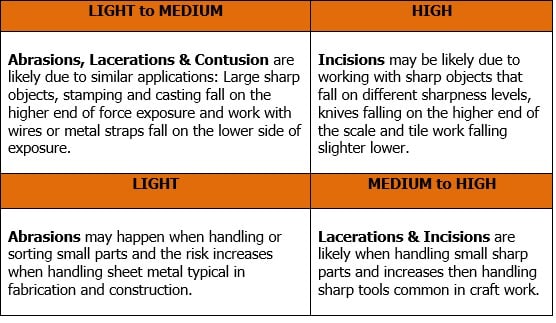

Here is a handy chart to help identify how risks can change depending on the application:

- Remember that scores are based on a scale of 0-10 for Force Exposure combined with Edge Sharpness! The higher the score, the more protection you need.

Material, coating and grip can make or break your level of safety:

By knowing the potential for injury and understanding the difference between materials and coatings, a safety manager can then choose a cut glove or sleeve that will provide the right protection for the job.

Grip is an important feature. When a worker is dealing with sharp edges, the worker has to have a sure grip on the object. And that’s not it. Oil, water or lube can definitely increase risk, so we need to take that into account as well.

Thicker coatings will resist tears and protect against abrasion from working with objects with rough edges and maximum grip coatings prevent slippage and reduce the chances of a worker coming into contact with a sharp edge. Just a few examples of different coatings include: latex, nitrile, foam nitrile, neofoam, polyurethane or PVC; and all of these coatings has a different job to do. Always remember that coatings do not provide extra protection against cut risk!

The material you choose needs to match the risk of the job. Whether you choose a Kevlar® material or HPPE, the yarn and fiber composition you choose is directly related to the level of protection the glove can offer.

Certain design features are used in the yarns in order to be designated protective gloves:

- Tensile Strength: The strength of the yarn of fiber must be strong enough so that it cannot be broken

- Abrasive Action: The fiber is hard enough that it will dull a blades edge before it can cut through

- Slippage: A blade will glide across the yarn without catching, so as material will not be cut

- Stretch: Most cut gloves are knit, not woven, so as to allow the glove to move ahead of the cutting edge

- Rolling: The ability of yarn fibers to roll as it comes in contact with cutting edge (it’s not easy to cut a moving target!)

- Loft: This is a soft thickness in the glove that makes cutting more difficult as cutting edge pressure is decreased

Understanding how a piece of protective equipment works will help safety managers and directors make more nimble and qualified purchasing decisions on products that will protect the worker. Think about it for a minute. If the person making the purchasing decisions isn’t familiar with the PPE that is needed to perform a task, how can we expect the end-user to use the right equipment?

The best way to make sure workers stay safe and companies stay in compliance is to make sure our safety intel is correct and up to date. Technologies change and while we can be creatures of habit, the old style gloves that we’ve been using for years just may not cut it anymore. Don’t take chances with hand protection; hands are what we rely upon to get the job done.

Safety: It's Your Life, It's Our Business