Do you know how to use NRR to calculate hearing protection?

The way hearing protection equipment works is often misunderstood and this can expose workers to the risk of potential hearing loss. Some contractors assume that the Noise Reduction Rating (NRR) is the actual level of protection that an earplug or earmuff will offer against a certain amount of noise.

Well folks, that’s not how this rating system works!

Take a pair of earmuffs with an NRR of 30 for instance. And let’s say that you work in an environment that produces a dose of noise at about 110 decibels. This is where there’s some confusion about the level of hearing protection that the device offers the wearer. Many think that it reduces noise by 30 decibels, bringing the noise dose down to 80 decibels and therefore well within safe levels. That is simply not the case.

To figure out the level of hearing protection a worker needs, some Math is required.

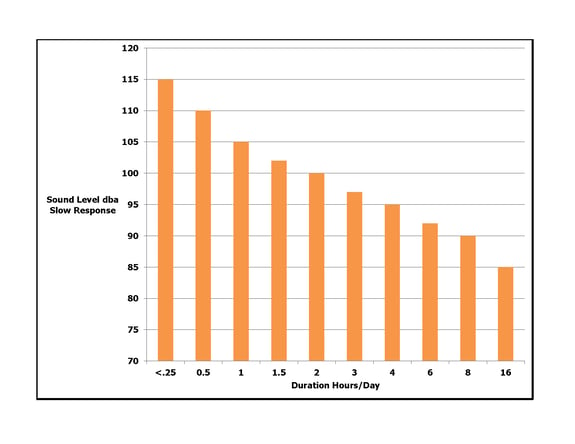

That only sounds complicated, but it really isn’t; the equation is simple. Essentially, we need to take that NRR of 30, subtract 7 and then divide by 2. By that calculation, we will reduce the original noise dose of 110 by 11.5 decibels bringing the level down to 98.5 decibels. A quick look at OSHA’s Permissible Exposure Limit (PEL) will tell you that only 2–3 hours of exposure per day is recommended at that level.

Diving even deeper into NIOSH’s limits will tell you that 15–30 minutes is your maximum exposure limit per day. Makes a big difference, doesn’t it?!

OSHA’s Permissible Exposure Limit

Now that we understand a little of the science behind NRR ratings, let’s take a look at the types of hearing protection available:

Types of Hearing Protection

- Earplugs: Foam plugs are made of a malleable material that shapes to the ear canal and expands to seal out noises. Silicone plugs rest near the opening of the ear canal instead of within it and are pre-molded to create a sound-proof barrier. You can usually get either type of material in a corded or uncorded earplug, depending on preference.

- Hearing Bands: These plugs are attached to a band that can go around a worker’s neck. This type of reusable earplugs comes in handy when you don’t want the plugs to come in contact with dirty or contaminated surfaces.

- Earmuffs:

- Cap Mounted: Designed for use with welding helmets, sandblasting hoods and hard caps, these earmuffs are slim, comfortable and feature a 2-point suspension along with liquid-filled ear cushions.

- Banded Earmuffs: These earmuffs are perfect for convenient and comfortable alignment to the head and feature replaceable ear cushions to provide a great seal, good fit and low surface pressure.

- Cap Mounted: Designed for use with welding helmets, sandblasting hoods and hard caps, these earmuffs are slim, comfortable and feature a 2-point suspension along with liquid-filled ear cushions.

- MultiMax® Earplugs: These uncorded earplugs are uniquely designed and offer two sizes in one. Workers can choose what tip fits, works best and is most comfortable to them.

- QB3® HYG: The Quiet series of earplug bands offer a variety of performance features. Great for visitors, managers or contractors that work in an environment with intermittent noise hazards. The band design prevents the earplugs from touching dirty surfaces.

- XLS Cap Model Earmuffs: Designed to fit comfortable under hard hats and faceshields to provide aggressive protection in low to moderate noise environments.

Using Ear Plugs Properly

OSHA has reported that work-related hearing loss costs businesses over $242 million every year in workers’ compensation. Each ear canal is different and what is considered proper placement varies from person to person so just putting an ear plug in doesn’t mean that it’s working. Using PPE should never be left to guesswork, so it is important to regularly inspect hearing protection systems, as well as train workers on how to properly use the devices. If workers don’t know how to use the devices properly, earplugs might as well be an accessory.

So, What’s the Employer’s Responsibility?

NIOSH reports that about 22 million workers are exposed to hazardous noise each year, demonstrating why it is so important to have a hearing conservation program in place. You might ask, what does this mean for me? Employers must provide workers with at least one type of earmuffs and one type of ear plugs, so that each person can choose a pair that fits him properly.

You also need to keep in mind that in order to get a reliable reading of what noise dose is present in a work environment, regular long term readings should be completed over the course of an entire day. Any less than that and you may not detect the changes in activity that might cause an excessive noise dose. Readings should also be taken whenever there are changes in production, process, environment or controls that may increase noise exposure. Employers should also make sure to calibrate the monitoring device regularly in order to make sure that the readings are accurate.

Every job has its hazards. By sticking to the standards and limiting the exposure risks, employers and management can reduce the impact these risks have on workers. Be a multi-tasker; protect workers’ precious hearing and your bottom line by providing the right hearing protection.

Safety: It's Your Life, It's Our Business.