Let's get real about lift truck safety. Forklift accidents are among the leading causes of injury, death and property damage in the workplace. Curious just how many people are impacted by forklift accidents on the job? More than 95,000 workers are involved in a forklift accident annually in the United States. What’s worse, 100 workers are killed by being struck by, run over or pinned by a forklift every year. Other risks include operating unsteady loads or falling off of open loading docks.

Think that’s bad? Get this, OSHA says 70% of accidents are avoidable with proper training and policy. That’s why you need to assess your equipment and surroundings every day before operating a forklift. Period. Don’t kid yourself by thinking it won’t happen on your site.

Spot these forklift dangers in your workplace:

|

|

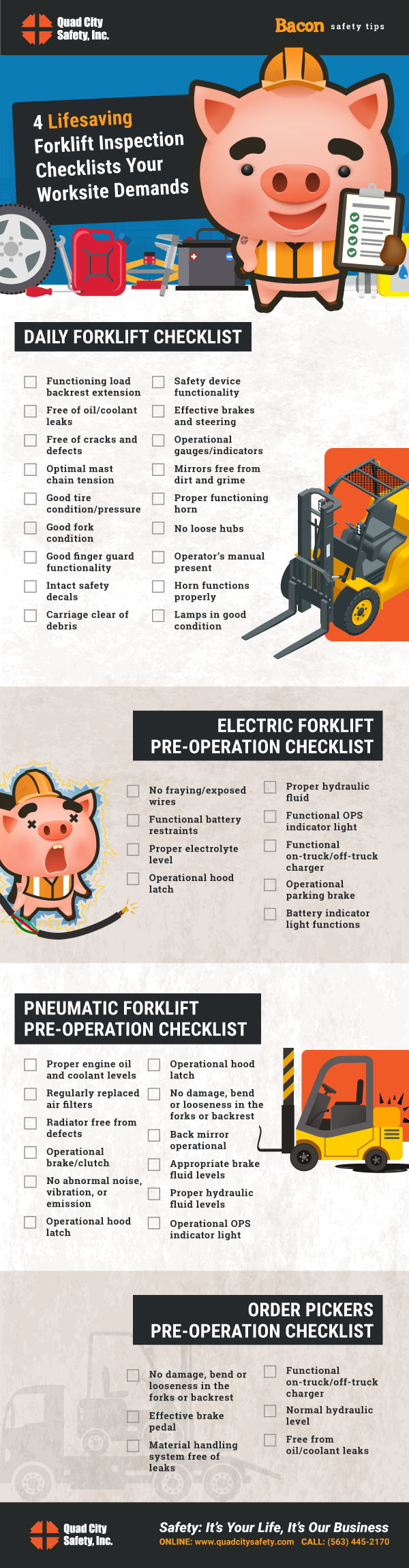

Use these checklists to prevent collisions, increase machine operation efficiency and reduce maintenance hazards in your workplace.

Whether you’re working in a warehouse, a construction site or a manufacturing facility, you need to create forklift operating procedures that keep your crew safe. Make sure every employee is aware of the real and present dangers that forklifts bring to any worksite. The only people operating lift trucks should meet OSHA’s training requirements in 1910.178 for material handling and storage.

Pedestrians especially need to be aware of their surroundings. Floor tapes, sign projectors, traffic signals, signs and barricades are effective means of controlling traffic areas. Forklift spot lights provide visual alerts of the danger zones around forklifts, so a worker doesn’t accidentally get in the forklift’s path. Don't just rely on safety equipment alone to protect your hide. Use common sense, inspect your equipment regularly and document training. That way, there will never be any doubt that your employees are following the rules.

Remember 70% of forklift accidents can be avoided just by following a few best practices. You’ll save yourself heartache, unnecessary expenses and your sanity. If you need help, click here. Improving worker safety is what we do.

Safety: It’s Your Life, It’s Our Business